Macro High-Speed Recordings Examine Every Chip in Detail, Hopefully Leading to Better Metalworking Fluids

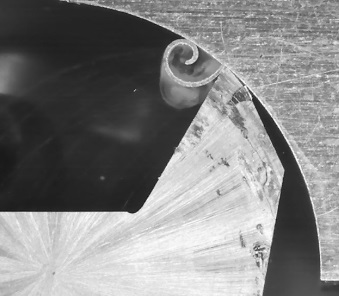

The recordings are impressive: Viewed in slow motion, a carbide milling tool removes a perfectly shaped brass chip.

In an extensive series of tests in the in-house Technology Center, the metalworking fluid experts from Blaser Swisslube analyzed machining processes down to the finest detail. The principle goal: to achieve better metalworking fluids faster through expertise and data.

The test setup. The idea grew out of a joint project with ETH Zurich.

The idea of capturing the machining process, chip formation and the behavior of the metalworking fluid more precisely than ever before through photos and videos came about as part of a joint project with the renowned ETH Zurich. The research and development team at Swiss metalworking fluids experts, Blaser Swisslube, set about the planning and implementation.

The use of a high- speed camera with a macro lens, which is placed behind a sight glass to keep the metalworking fluid at a distance, should make uniquely sharp, precise recordings possible. A ring light was used to provide the necessary light intensity, as well as a carbide cutter with a helix angle of 0° that was specially ground for this particular test.

The results are fascinating: The high-speed recordings showed for the first time that the mechanism of action of oil-free, water-soluble metalworking fluid, Synergy 735 -- namely its improved lubricating effect at higher temperatures -- also occurs during machining and is fast enough to optimize milling processes. Synergy 735 thus changes its properties and adapts to the machining process like a chameleon.

"Our Technology Center allows us to take a closer look than our competitors. This focus on all the details and the cooperation between our chemists and the machining experts enables us to develop metalworking fluids that improve processes sustainably, reduce production costs and prolong tool life," explains Marc Blaser, CEO of Blaser Swisslube.

When machining titanium, the highest temperatures are reached near the cutting edge and in the chip.

As the Synergy 735 metalworking fluid used in the test described cools down, it becomes clear again, keeping the machine clean and allowing a good view of the machining process. The advantages also include the neutral odor and excellent skin compatibility. Synergy 735 provides flawless finishes on a variety of materials from aluminum and titanium alloys to CrNi steels. The minimal foaming means the coolant is also ideally suited to high-pressure systems.

Measuring Wear Reveals Potential Savings

A microscope camera for measuring wear automatically takes microscopic images of the turning plate every two minutes.

Lead-free brass glides over the cutting edge and forms a thin chip.

"Tool wear often limits the economic viability of a process. The new measuring options give us meaningful information, directly from the machine," explains Dr. Linus Meier, a tribology specialist at Blaser Swisslube. The optimized data flow means that changes to the metalworking fluid can be implemented more quickly and easily. "This is good news for our customers. That's because high-performance metalworking fluids offer enormous savings potential in production, whether through increased productivity or reduced tool wear," emphasizes Meier.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::